Fasteners and Machining: Tailored Solutions for every single Manufacturing Demand

Fasteners and Machining: Tailored Solutions for every single Manufacturing Demand

Blog Article

Browsing the Globe of Fasteners and Machining: Methods for Precision and Rate

In the detailed realm of fasteners and machining, the mission for precision and rate is a perpetual challenge that requires meticulous attention to information and strategic planning. From recognizing the varied variety of fastener kinds to choosing optimal products that can endure extensive needs, each action in the process plays a pivotal role in attaining the desired outcome. Accuracy machining methods additionally boost the intricacy of this craft, needing a delicate equilibrium between technological knowledge and ingenious approaches. As we explore the techniques that can improve both speed and effectiveness in this domain, the interaction in between quality control steps and functional quality becomes an essential focal factor.

Understanding Fastener Types

When selecting bolts for a project, comprehending the numerous types readily available is critical for making certain ideal efficiency and dependability. Bolts are used with nuts to hold products with each other, while screws are flexible fasteners that can be utilized with or without a nut, depending on the application. Washing machines are important for distributing the tons of the bolt and stopping damage to the material being fastened.

Picking the Right Products

Comprehending the significance of choosing the ideal materials is vital in ensuring the optimal performance and reliability of the picked fastener types talked about previously. When it involves fasteners and machining applications, the material choice plays an important role in establishing the total stamina, durability, deterioration resistance, and compatibility with the desired atmosphere. Different products use varying buildings that can considerably impact the efficiency of the fasteners.

Usual products used for fasteners include steel, stainless steel, titanium, brass, and light weight aluminum, each having its unique strengths and weaknesses. Steel is renowned for its high stamina and sturdiness, making it ideal for a wide array of applications. Stainless steel offers excellent rust resistance, ideal for settings vulnerable to moisture and chemicals. Aluminum is corrosion-resistant and light-weight, making it appropriate for applications where weight reduction is critical. Brass is often picked for its aesthetic charm and outstanding conductivity. Titanium is known for its outstanding strength-to-weight ratio, making it excellent for high-performance applications. Picking the ideal product involves thinking about aspects such as toughness needs, ecological conditions, and spending plan restrictions to ensure the preferred performance and longevity of the fasteners.

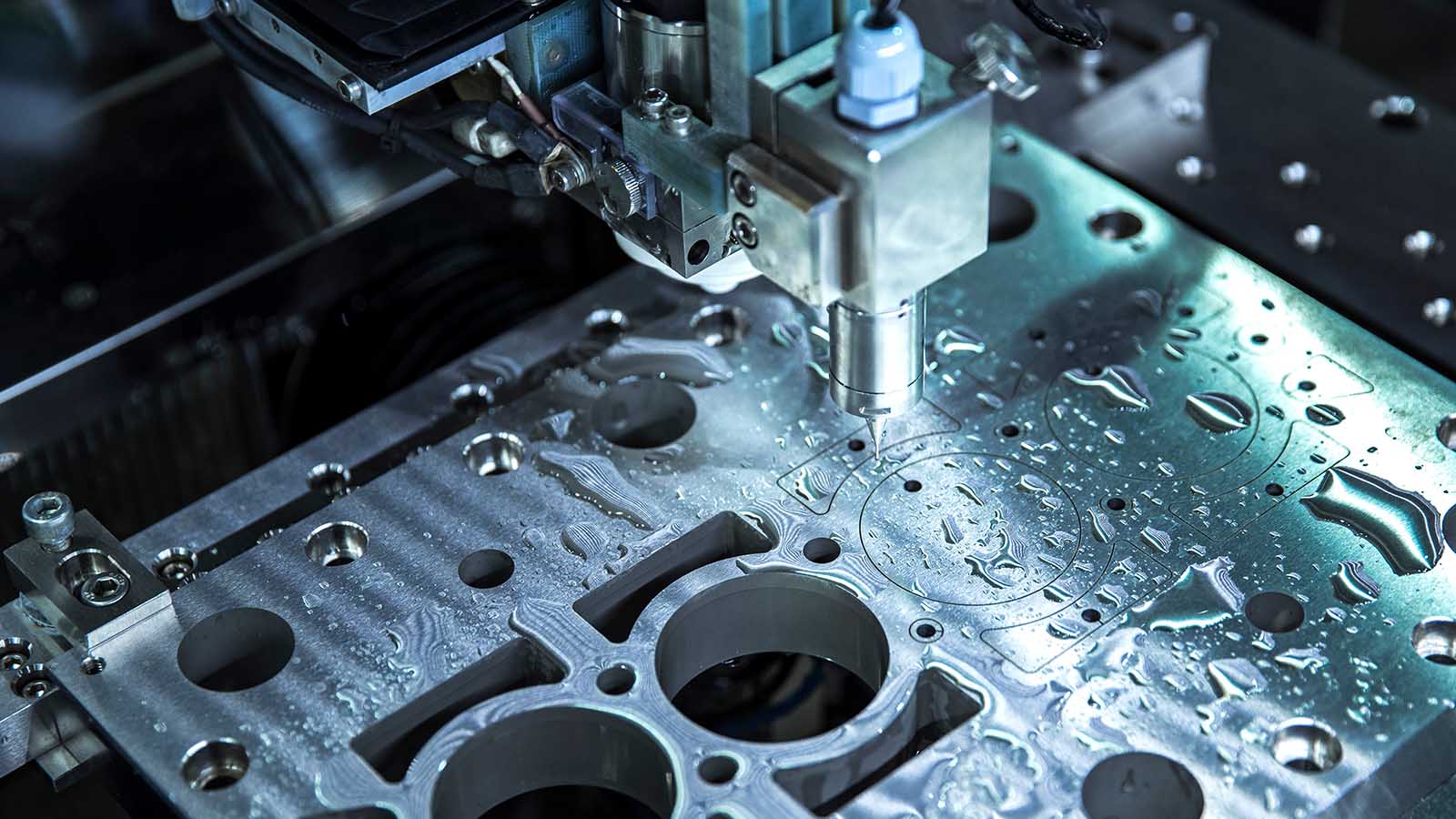

Accuracy Machining Techniques

Along with CNC machining, various other accuracy strategies like grinding, transforming, milling, and boring play important functions in bolt manufacturing. Grinding assists achieve great surface area finishes and limited dimensional tolerances, while transforming is commonly used to produce round elements with exact diameters. Milling and boring operations are essential for shaping and creating openings in bolts, guaranteeing they satisfy specific specifications and function properly.

Enhancing Speed and Performance

To enhance bolt production procedures, it is crucial to simplify operations and execute reliable strategies that complement precision machining techniques. Automated systems can manage recurring tasks with accuracy and speed, allowing workers to focus on even more facility and value-added activities. By combining these approaches, producers can achieve a balance between rate and precision, eventually improving their competitive side in the bolt sector.

Quality Assurance Steps

Implementing extensive quality assurance procedures is important in making certain the dependability and uniformity of fastener items in the production procedure. Quality assurance procedures encompass various phases, beginning from why not find out more the choice of resources to the last inspection of the ended up fasteners. One essential element of high quality control is carrying out detailed product examinations to validate conformity with specs. This includes examining variables such as material durability, make-up, and stamina to assure that the fasteners fulfill market requirements. Furthermore, monitoring the machining processes is vital to support dimensional precision and surface finish quality. Using innovative innovation, such as automatic assessment systems and accuracy measuring tools, can enhance the precision and efficiency of top quality control treatments.

Regular calibration of tools and equipment is important to keep uniformity in production and ensure that bolts meet the needed tolerances. Implementing rigorous methods for identifying and dealing with non-conformities or defects is crucial in preventing substandard products from getting in the marketplace. By establishing a detailed quality assurance structure, suppliers can promote the online reputation of their brand and deliver fasteners that fulfill the highest criteria of efficiency have a peek here and resilience.

Conclusion

In the detailed world of bolts and machining, the mission for precision and rate is a continuous obstacle that demands meticulous attention to detail more helpful hints and calculated planning. When it comes to fasteners and machining applications, the material option plays a critical function in establishing the total toughness, durability, rust resistance, and compatibility with the intended atmosphere. Accuracy machining includes various innovative techniques that ensure the limited tolerances and requirements required for fasteners.In enhancement to CNC machining, various other precision methods like grinding, turning, milling, and exploration play crucial functions in bolt production.To optimize fastener manufacturing procedures, it is vital to improve procedures and implement effective methods that complement accuracy machining techniques.

Report this page